Nā kikoʻī

ʻO SILIKE Si-TPV 2250 Series kahi elastomer thermoplastic silicone-based vulcanized i hoʻolālā ʻia e hoʻomaikaʻi i nā mea hoʻohua EVA. Hana ʻia ka Si-TPV 2250 Series me ka hoʻohana ʻana i kahi ʻenehana kūikawā e hōʻoiaʻiʻo ana ua hoʻopuehu like ʻia ka rubber silicone ma EVA ma ke ʻano he 1-3 micron particles. Hoʻohui kēia mea hoʻololi kūikawā no ka mea hoʻohua EVA i ka ikaika, ka paʻakikī, a me ke kūpaʻa abrasion o nā elastomers thermoplastic me nā waiwai i makemake ʻia o ka silicone, me ka palupalu, kahi manaʻo siliki, ke kūpaʻa UV, a me ke kūpaʻa kemika. Hiki ke hana hou ʻia a hoʻohana hou ʻia i nā kaʻina hana hana kuʻuna.

He kūpono loa nā mea Si-TPV 2250 Series Eco-Friendly Soft Touch Material me ka ethylene-vinyl acetate (EVA) a lawelawe ma ke ʻano he mea hoʻololi silicone hou no ka EVA Foaming, Nā hoʻonā no ka hoʻomaikaʻi ʻana i nā mea EVA foam i nā noi e like me nā kapuaʻi kāmaʻa, nā huahana sanitary, nā huahana leʻaleʻa haʻuki, nā moena papahele, nā moena yoga, a me nā mea hou aku.

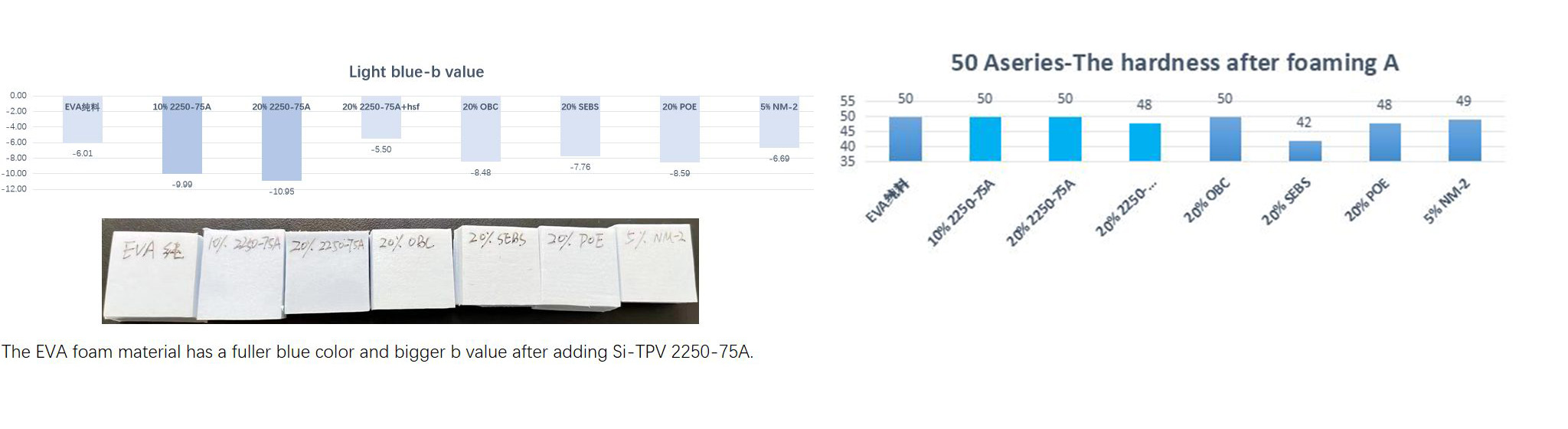

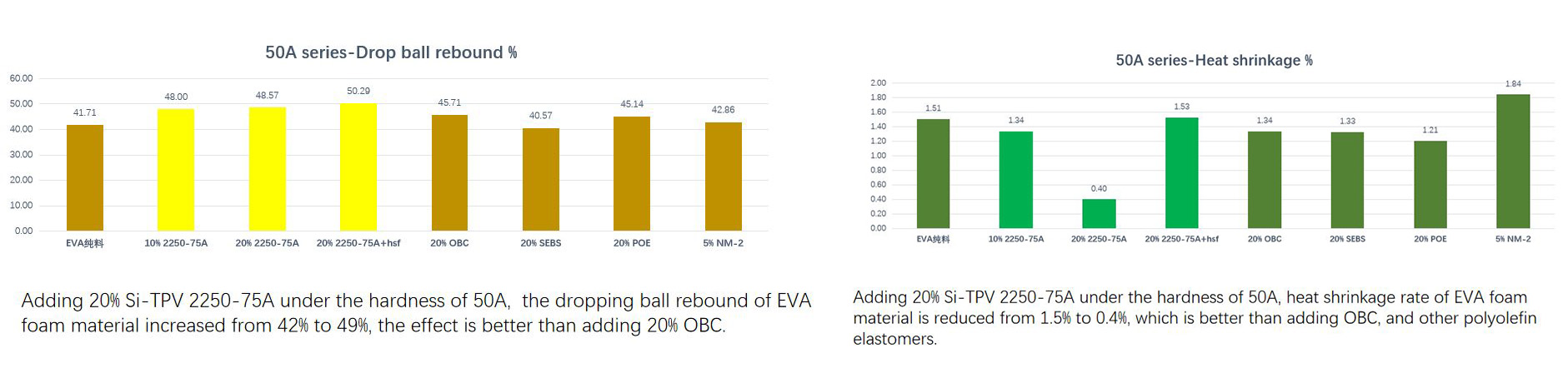

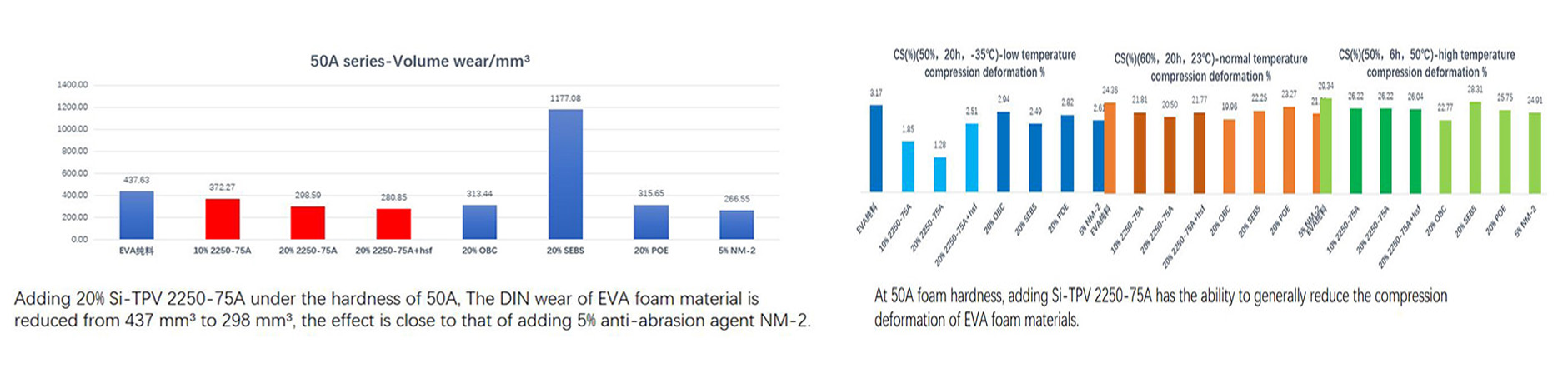

Ke hoʻohālikelike ʻia me OBC a me POE, hoʻemi ʻo Highlight i ka hoʻonohonoho compression a me ka wikiwiki o ka emi ʻana o ka wela o nā mea huʻa EVA, hoʻomaikaʻi i ka elasticity a me ka palupalu o ka EVA foaming, hoʻomaikaʻi i ke kū'ē ʻana i ka paheʻe a me ka anti-abrasion, a ua hoʻemi ʻia ke kapa DIN mai 580 mm3 a i 179 mm3 a hoʻomaikaʻi i ka saturation kala o nā mea huʻa EVA.

ʻO ia ka mea i hōʻoia ʻia he mau hoʻonā mea hoʻoheheʻe Eva Foam kūpono.

Nā Pōmaikaʻi Koʻikoʻi

Ke kūpaʻa Ke kūpaʻa

- ʻO ka ʻenehana solvent-free holomua, me ka ʻole o ka plasticizer, ʻaʻohe aila palupalu, a ʻaʻohe ʻala.

- Ka palekana o ke kaiapuni a me ka hiki ke hana hou ʻia.

- Loaʻa i loko o nā ʻano hana hoʻoponopono.

Mea Hoʻololi Si-TPV no ka EVA Foaming Nā hihia haʻawina

Loaʻa i ka Si-TPV 2250 Series ka pā palupalu no ka ʻili no ka manawa lōʻihi, ke kūpaʻa maikaʻi i ka ʻili, a ʻaʻole pono e hoʻohui i nā plasticizers a i ʻole nā mea palupalu. Pale pū ia i ka ua ma hope o ka hoʻohana lōʻihi. Ma ke ʻano he mea hoʻololi huʻa Eva palupalu kūpono loa a hou, kūpono loa ia no ka hoʻomākaukau ʻana i nā mea hoʻohua EVA māmā loa, elastic loa, a aloha i ke kaiapuni.

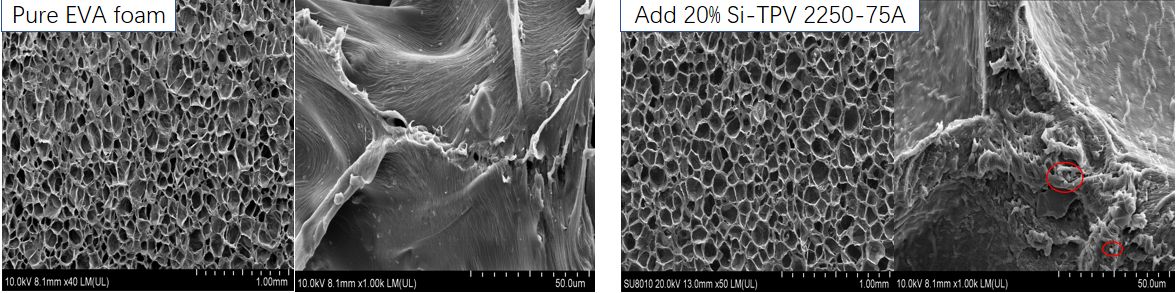

Ma hope o ka hoʻohui ʻana i ka Si-TPV 2250-75A, e emi iki ana ka nui o nā cell pehu o ka huʻa EVA, e mānoanoa ana ka paia pehu, a e hoʻopuehu ʻia ʻo Si-TPV i loko o ka paia pehu, a lilo ka paia pehu i ʻinoʻino.

Hoʻohālikelike ʻana o Si-TPV2250-75A a me nā hopena hoʻohui elastomer polyolefin i ka huʻa EVA

Noi

ʻO ka mea hoʻololi Si-TPV ʻōmaʻomaʻo hou e pili ana i ke kaiapuni e hoʻoikaika ana i ka mea hoʻohua EVA i hoʻololi hou i nā ʻano hana o kēlā me kēia lā a me nā ʻoihana. e like me nā kāmaʻa, nā huahana hoʻomaʻemaʻe, nā uluna ʻauʻau, nā huahana leʻaleʻa haʻuki, nā moena papahele/yoga, nā mea pāʻani, nā ʻōpala, nā mea lapaʻau, nā lako pale, nā huahana wai ʻole, a me nā panela photovoltaic…

Inā ʻoe e kālele ana i nā hopena no ka hoʻopūʻū supercritical, ʻaʻole mākou maopopo inā no ʻoe ia, akā ʻo kēia mea hoʻololi Si-TPV e hoʻololi hou ana i ka ʻenehana hoʻopūʻū kemika. No nā mea hana hoʻopūʻū EVA hiki ke lilo i ala ʻē aʻe e hana ai i nā huahana māmā a maʻalahi me nā ana kikoʻī.

Nā Hoʻonā:

Hoʻonui i nā EVA Foams: Ke hoʻoponopono nei i nā pilikia EVA Foam me nā mea hoʻololi Si-TPV

1. Hoʻolauna i nā mea hana EVA Foam

ʻO nā mea huʻa EVA he ʻano huʻa pani-cell i hana ʻia mai ka hui ʻana o nā copolymers ethylene a me vinyl acetate, me ka polyethylene a me nā mea hoʻohua like ʻole a me nā mea hoʻoulu i hoʻokomo ʻia i ka wā o ka hana ʻana. Kaulana no kona cushioning kiʻekiʻe, ka hoʻopili ʻana i ka haʻalulu, a me ke kūpaʻa wai, hōʻike ka huʻa EVA i kahi ʻano māmā akā paʻa e hāʻawi ana i ka insulation thermal maikaʻi loa. ʻO kona mau waiwai kupaianaha e hoʻolilo i ka huʻa EVA i mea versatile, hoʻohana nui ʻia i nā huahana o kēlā me kēia lā a me nā noi kūikawā ma nā ʻoihana like ʻole, e like me nā kapuaʻi kāmaʻa, nā moena huʻa palupalu, nā poloka yoga, nā papa ʻauʻau, ka papahele papahele, a pēlā aku.

2. He aha nā palena o nā EVA Foams Kuʻuna?

Manaʻo ka poʻe he nui ʻo ka mea huʻa EVA ka hui kūpono o ka pūpū paʻakikī a me ka pūpū palupalu. Eia nō naʻe, ua kaupalena ʻia ka hoʻohana ʻana i nā mea huʻa EVA i kekahi ʻano ma muli o kona kūpaʻa ʻole i ka ʻelemakule, ke kūpaʻa ʻana i ka flexure, ka elasticity, a me ke kūpaʻa ʻana i ka abrasion. ʻO ka piʻi ʻana o ETPU i nā makahiki i hala iho nei a me ka hoʻohālikelike ʻana o nā laʻana e hana pū i nā kāmaʻa huʻa EVA i loaʻa ka paʻakikī haʻahaʻa, ka rebound kiʻekiʻe, ka deformation compression haʻahaʻa, a me nā waiwai hou ʻē aʻe.

Eia kekahi, nā pilikia kaiapuni a me ke olakino o ka hana ʻana o ka EVA Foam.

ʻO nā huahana EVA i hoʻolako ʻia ma ka mākeke i kēia manawa ua hoʻomākaukau ʻia e ke ʻano hoʻohua kemika a hoʻohana nui ʻia no nā huahana e like me nā mea kāmaʻa, nā moena lepo, a me nā mea like e pili pono ana i nā kino kanaka. Eia nō naʻe, ʻo ka mea hoʻohua EVA i hoʻomākaukau ʻia e ke ʻano a me ke kaʻina hana he mau pilikia palekana kaiapuni a me ke olakino like ʻole, a ʻoi aku hoʻi, ʻo nā mea ʻino (ʻoi aku ka formamide) e hoʻokaʻawale mau ʻia mai loko o ka huahana no ka manawa lōʻihi.