Nā kikoʻī

ʻO ka SILIKE Si-TPV 2150 Series kahi elastomer vulcanizate silicone-based, i hoʻomohala ʻia me ka hoʻohana ʻana i ka ʻenehana hoʻohālikelike holomua. Hoʻopuehu kēia kaʻina hana i ka silicone rubber i loko o SEBS ma ke ʻano he mau ʻāpana liʻiliʻi, mai 1 a 3 microns ma lalo o kahi microscope. Hoʻohui kēia mau mea kū hoʻokahi i ka ikaika, ka paʻakikī, a me ke kūpaʻa ʻana o ka abrasion o nā elastomers thermoplastic me nā waiwai i makemake ʻia o ka silicone, e like me ka palupalu, kahi manaʻo siliki, a me ke kūʻē ʻana i ka mālamalama UV a me nā kemika. Eia kekahi, hiki ke hana hou ʻia nā mea Si-TPV a hiki ke hoʻohana hou ʻia i nā kaʻina hana hana kuʻuna.

Hiki ke hoʻohana pololei ʻia ʻo Si-TPV ma ke ʻano he mea maka, i hoʻolālā kūikawā ʻia no nā noi hoʻopili palupalu i nā mea uila hiki ke hoʻohana ʻia, nā hihia pale no nā mea uila, nā ʻāpana kaʻa, nā TPE kiʻekiʻe, a me nā ʻoihana uea TPE.

Ma waho aʻe o kona hoʻohana pololei ʻana, hiki iā Si-TPV ke lawelawe ma ke ʻano he mea hoʻololi polymer a me ka mea hoʻohui hana no nā elastomers thermoplastic a i ʻole nā polymers ʻē aʻe. Hoʻonui ia i ka elasticity, hoʻomaikaʻi i ka hana ʻana, a hoʻonui i nā waiwai o ka ʻili. Ke hui pū ʻia me TPE a i ʻole TPU, hāʻawi ʻo Si-TPV i ka laumania o ka ʻili lōʻihi a me kahi manaʻo paʻi ʻoluʻolu, me ka hoʻomaikaʻi ʻana i ke kū'ē ʻana i ke kahakaha a me ka abrasion. Hoʻemi ia i ka paʻakikī me ka ʻole o ka hoʻopilikia maikaʻi ʻole i nā waiwai mechanical a hāʻawi i ka pale ʻana i ka ʻelemakule, ka melemele, a me ka ʻino. Hiki iā ia ke hana i kahi hoʻopau matte makemake ʻia ma ka ʻili.

ʻAʻole e like me nā mea hoʻohui silicone maʻamau, hāʻawi ʻia ʻo Si-TPV ma ke ʻano pellet a hana ʻia e like me ka thermoplastic. Hoʻopuehu maikaʻi a like hoʻi ia ma loko o ka matrix polymer, me ka copolymer e pili kino ana i ka matrix. Hoʻopau kēia i ka hopohopo o ka neʻe ʻana a i ʻole nā pilikia "pua", e hoʻolilo ana iā Si-TPV i hopena kūpono a hou no ka hoʻokō ʻana i nā ʻili palupalu silky i nā elastomers thermoplastic a i ʻole nā polymers ʻē aʻe. a ʻaʻole pono nā hana hana hou a i ʻole nā ʻanuʻu uhi.

Nā Pōmaikaʻi Koʻikoʻi

- Ma TPE

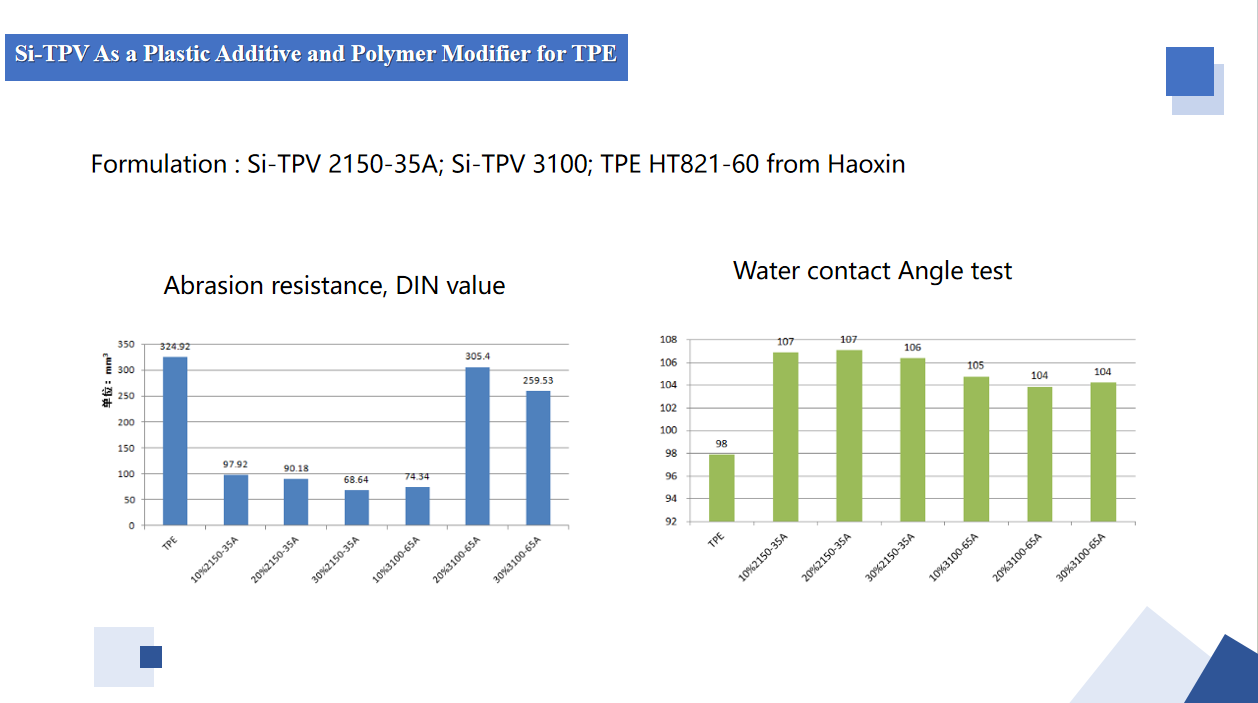

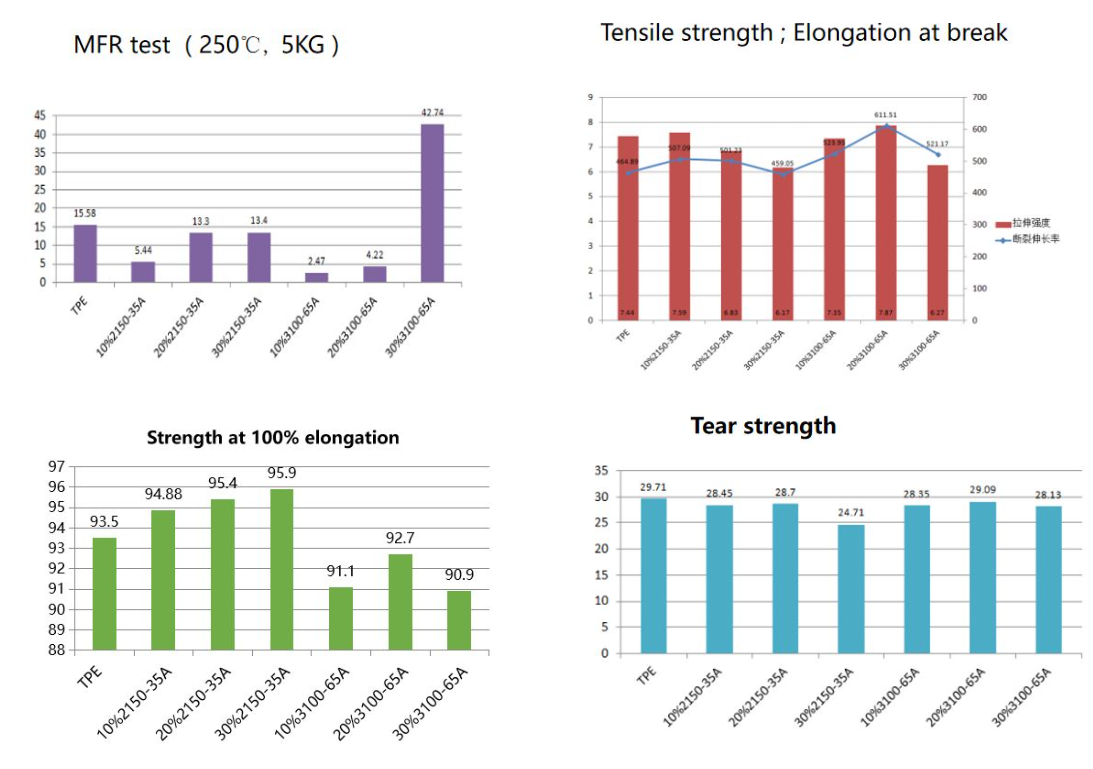

- 1. Ke kū'ē ʻana i ka abrasion

- 2. Ke kūpaʻa ʻana i nā ʻōpala me kahi kihi pili wai liʻiliʻi

- 3. E hōʻemi i ka paʻakikī

- 4. ʻAneʻane ʻaʻohe mana i nā waiwai mechanical me kā mākou moʻo Si-TPV 2150

- 5. Nā haptics maikaʻi loa, pā maloʻo a siliki, ʻaʻohe pua ma hope o ka hoʻohana lōʻihi

Ke kūpaʻa Ke kūpaʻa

- ʻO ka ʻenehana solvent-free holomua, me ka ʻole o ka plasticizer, ʻaʻohe aila palupalu, a ʻaʻohe ʻala.

- Ka palekana o ke kaiapuni a me ka hiki ke hana hou ʻia.

- Loaʻa i loko o nā ʻano hana hoʻoponopono.

Nā Haʻawina Hihia no ka mea hoʻohui palakiko Si-TPV a me ka mea hoʻololi polymer

Loaʻa i ka moʻo Si-TPV 2150 nā ʻano o ka pā palupalu no ka ʻili no ka manawa lōʻihi, ke kūpaʻa maikaʻi i nā ʻōpala, ʻaʻohe plasticizer a me ka softener i hoʻohui ʻia, a ʻaʻohe ua ma hope o ka hoʻohana lōʻihi, e lawelawe ana ma ke ʻano he mea hoʻohui plastik a me ka mea hoʻololi polymer, i hoʻohana kūpono ʻia no ka hoʻomākaukau ʻana i nā elastomers thermoplastic ʻoluʻolu a silky.

Ke hoʻohālikelike nei i nā hopena o ka Si-TPV Plastic Additive a me ka Polymer Modifier ma ka hana TPE

Noi

Hana ʻo Si-TPV ma ke ʻano he mea hoʻololi manaʻo hou a me ka mea hoʻohui hana no nā elastomers thermoplastic a me nā polymers ʻē aʻe. Hiki ke hoʻohui ʻia me nā elastomers like ʻole a me nā ʻenekinia a i ʻole nā plastics maʻamau, e like me TPE, TPU, SEBS, PP, PE, COPE, EVA, ABS, a me PVC. Kōkua kēia mau hoʻonā i ka hoʻonui ʻana i ka pono o ka hana ʻana a hoʻomaikaʻi i ka hana kū'ē i ke kahakaha a me ka abrasion o nā ʻāpana i hoʻopau ʻia.

ʻO kahi pōmaikaʻi nui o nā huahana i hana ʻia me nā hui TPE a me Si-TPV ʻo ia ka hoʻokumu ʻana i kahi ʻili palupalu siliki ʻaʻole e paʻa - ʻo ia ka ʻike paʻi a nā mea hoʻohana hope e manaʻo ai mai nā mea a lākou e hoʻopā pinepine ai a ʻaʻahu paha. Hoʻonui kēia hiʻohiʻona kū hoʻokahi i ka laulā o nā noi kūpono no nā mea elastomer TPE ma nā ʻoihana he nui. Eia kekahi, ʻo ka hoʻokomo ʻana iā Si-TPV ma ke ʻano he mea hoʻololi e hoʻonui i ka maʻalahi, ka elasticity, a me ke kūpaʻa o nā mea elastomer, ʻoiai e hoʻolilo ana i ke kaʻina hana i ʻoi aku ka maikaʻi o ke kumukūʻai.

Nā Hoʻonā:

Ke paio nei e hoʻoikaika i ka hana TPE? Hāʻawi nā mea hoʻohui plastik Si-TPV a me nā mea hoʻololi polymer i ka pane

Hoʻolauna i nā TPE

Ua hoʻokaʻawale ʻia nā elastomers Thermoplastic (TPE) e ka haku mele kemika, me Thermoplastic Olefins (TPE-O), Styrenic Compounds (TPE-S), Thermoplastic Vulcanizates (TPE-V), Polyurethanes (TPE-U), Copolyesters (COPE), a me Copolyamides (COPA). ʻOiai ua hana nui ʻia nā polyurethanes a me nā copolyesters no kekahi mau hoʻohana, ʻoi aku ka maikaʻi o nā koho ʻoi aku ka maikaʻi o ke kumukūʻai e like me TPE-S a me TPE-V no nā noi.

ʻO nā TPE maʻamau he mau hui kino o ka laholio a me nā thermoplastics, akā ʻokoʻa nā TPE-V ma ka loaʻa ʻana o nā ʻāpana laholio i hoʻopili hapa ʻia a piha paha, e hoʻomaikaʻi ana i kā lākou hana. Loaʻa i nā TPE-V nā seti compression haʻahaʻa, ʻoi aku ka maikaʻi o ke kūpaʻa kemika a me ka abrasion, a me ke kūpaʻa wela kiʻekiʻe, e kūpono ai lākou no ka hoʻololi ʻana i ka laholio i loko o nā sila. I ka hoʻohālikelike ʻana, hāʻawi nā TPE maʻamau i ka maʻalahi o ka hoʻohuihui ʻana, ka ikaika tensile kiʻekiʻe, ka elasticity, a me ke kala, e kūpono ai lākou no nā huahana e like me nā waiwai kūʻai, nā mea uila, a me nā mea lapaʻau. Hoʻopili maikaʻi lākou i nā substrates paʻa e like me PC, ABS, HIPS, a me Nylon, he mea maikaʻi ia no nā noi pā palupalu.

Nā pilikia me nā TPE

Hoʻohui nā TPE i ka elasticity me ka ikaika mechanical a me ka hiki ke hana ʻia, e hoʻolilo iā lākou i mea maʻalahi loa. ʻO kā lākou mau waiwai elastic, e like me ka compression set a me ka elongation, mai ka pae elastomer, ʻoiai ʻo ka ikaika tensile a me ka haehae e hilinaʻi ana i ka ʻāpana plastic.

Hiki ke hana ʻia nā TPE e like me nā thermoplastics maʻamau i nā mahana kiʻekiʻe, kahi e komo ai lākou i ka pae hoʻoheheʻe, e ʻae ana i ka hana pono ʻana me ka hoʻohana ʻana i nā lako hana plastic maʻamau. He mea koʻikoʻi nō hoʻi ko lākou pae mahana hana, e hoʻolōʻihi ana mai nā mahana haʻahaʻa loa—kokoke i ke kiko hoʻololi aniani o ka pae elastomer—a i nā mahana kiʻekiʻe e kokoke ana i ke kiko hoʻoheheʻe o ka pae thermoplastic—e hoʻohui ana i ko lākou versatility.

Eia nō naʻe, me kēia mau pono, ke hoʻomau nei kekahi mau pilikia i ka hoʻonui ʻana i ka hana o nā TPE. ʻO kahi pilikia nui ka paʻakikī i ke kaulike ʻana i ka elasticity me ka ikaika mechanical. ʻO ka hoʻonui ʻana i kekahi waiwai e hele pinepine mai i ke kumukūʻai o kekahi, e paʻakikī ai i nā mea hana ke hoʻomohala i nā ʻano TPE e mālama i kahi kaulike mau o nā hiʻohiʻona i makemake ʻia. Eia kekahi, hiki i nā TPE ke hōʻino ʻia i ka ʻili e like me nā ʻōpala a me ka marring, hiki ke hoʻopilikia maikaʻi ʻole i ke ʻano a me ka hana o nā huahana i hana ʻia mai kēia mau mea.